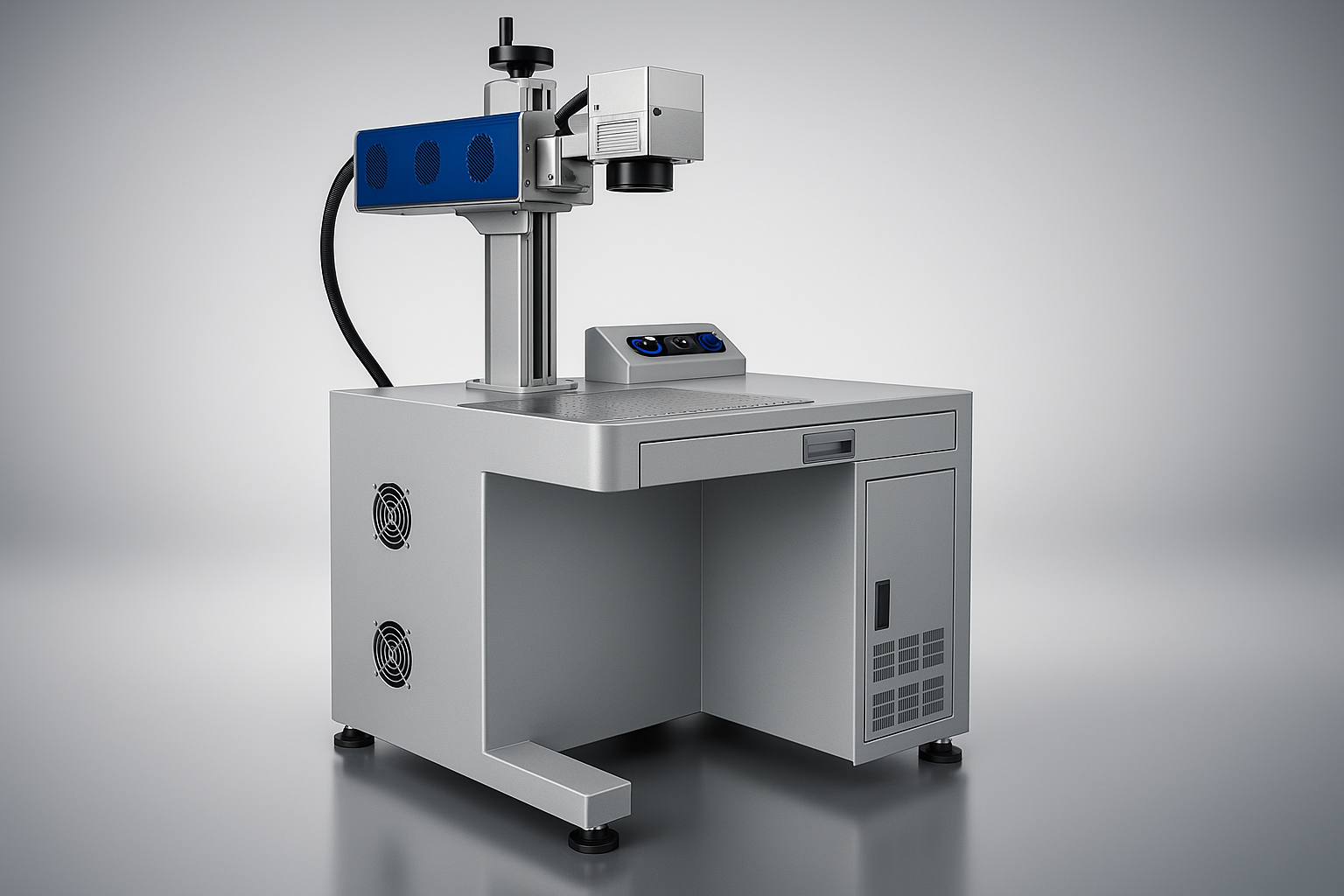

IJS’s Laser Marking Systems utilize focused beams of light to create permanent, high-contrast marks without the use of inks or consumables. The laser’s energy alters the surface composition through ablation, engraving, or color change, resulting in marks that are both durable and precise. This contactless process ensures zero contamination and minimal maintenance, embodying sustainable, long-term reliability for critical industrial applications.

Laser marking is ideal for products that demand tamper-proof identification, traceability, and longevity. It delivers precise results even at high line speeds, maintaining legibility across materials and environments.

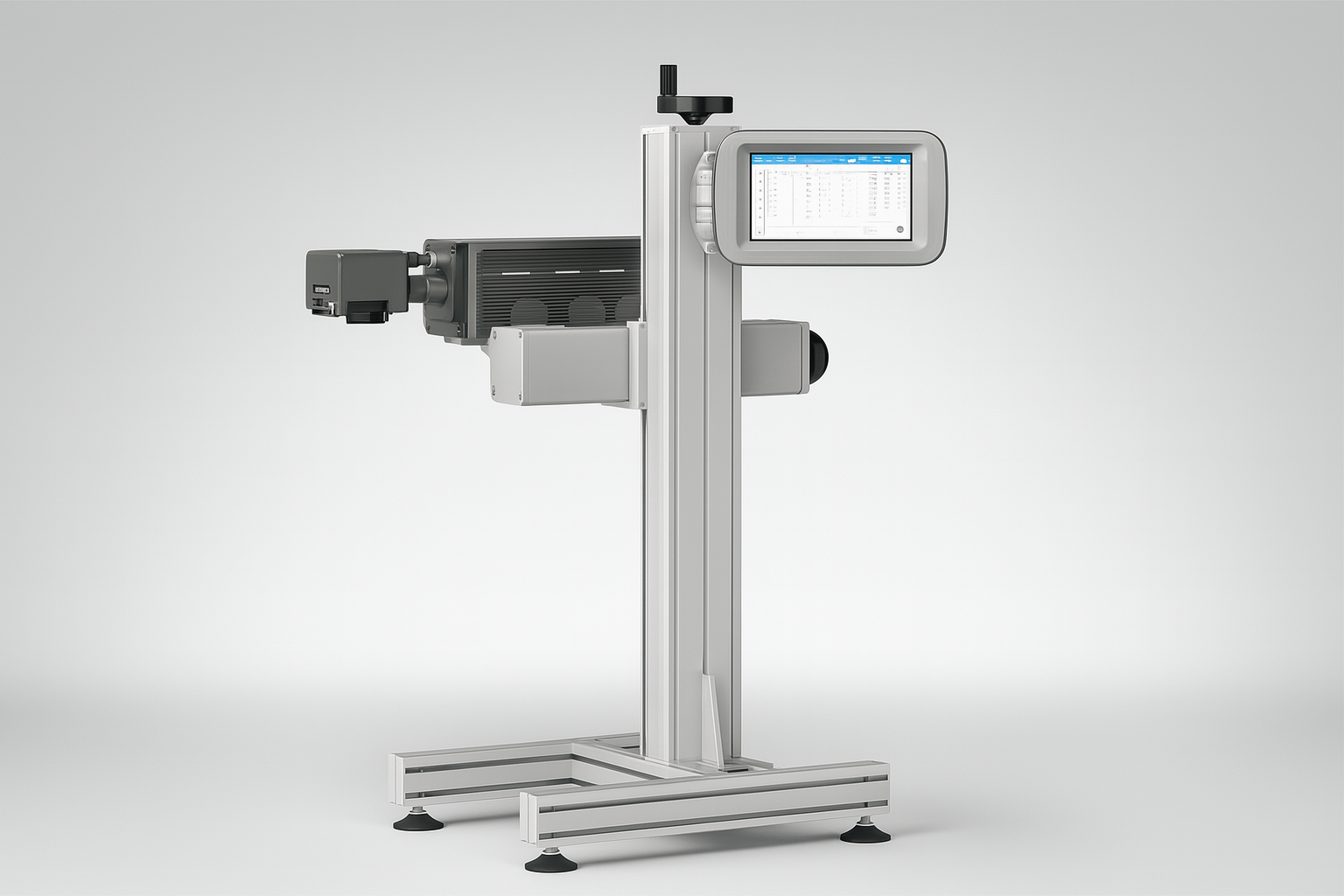

The IJS CO2 Laser Marking Machine is built to help you mark your products clearly and quickly without touching them. It’s ideal for printing dates, batch numbers, barcodes, and other important details directly onto packaging materials like films, laminates, PET bottles, and paper. This machine is a great fit for pharma, beverages, cosmetics, and everyday consumer goods, where packaging needs to look clean, stay readable, and keep up with fast production speeds. And because it doesn’t use ink or chemicals, it’s easy to maintain and better for the environment, saving you time, cost, and hassle.

The IJS UV Laser Marking Machine is made for the kinds of materials that can’t handle heat. It uses a special “cold marking” process that lets you add sharp, permanent codes and text without burning, melting, or damaging the surface. It works especially well on glass, thin films, PET, PP, PE, HDPE, and other sensitive materials often used in pharmaceutical, personal care, and specialty packaging. If you’re packaging products in clear bottles, medical plastics, or soft containers, this machine gives you the clean, detailed marking you need without any risk to the product.

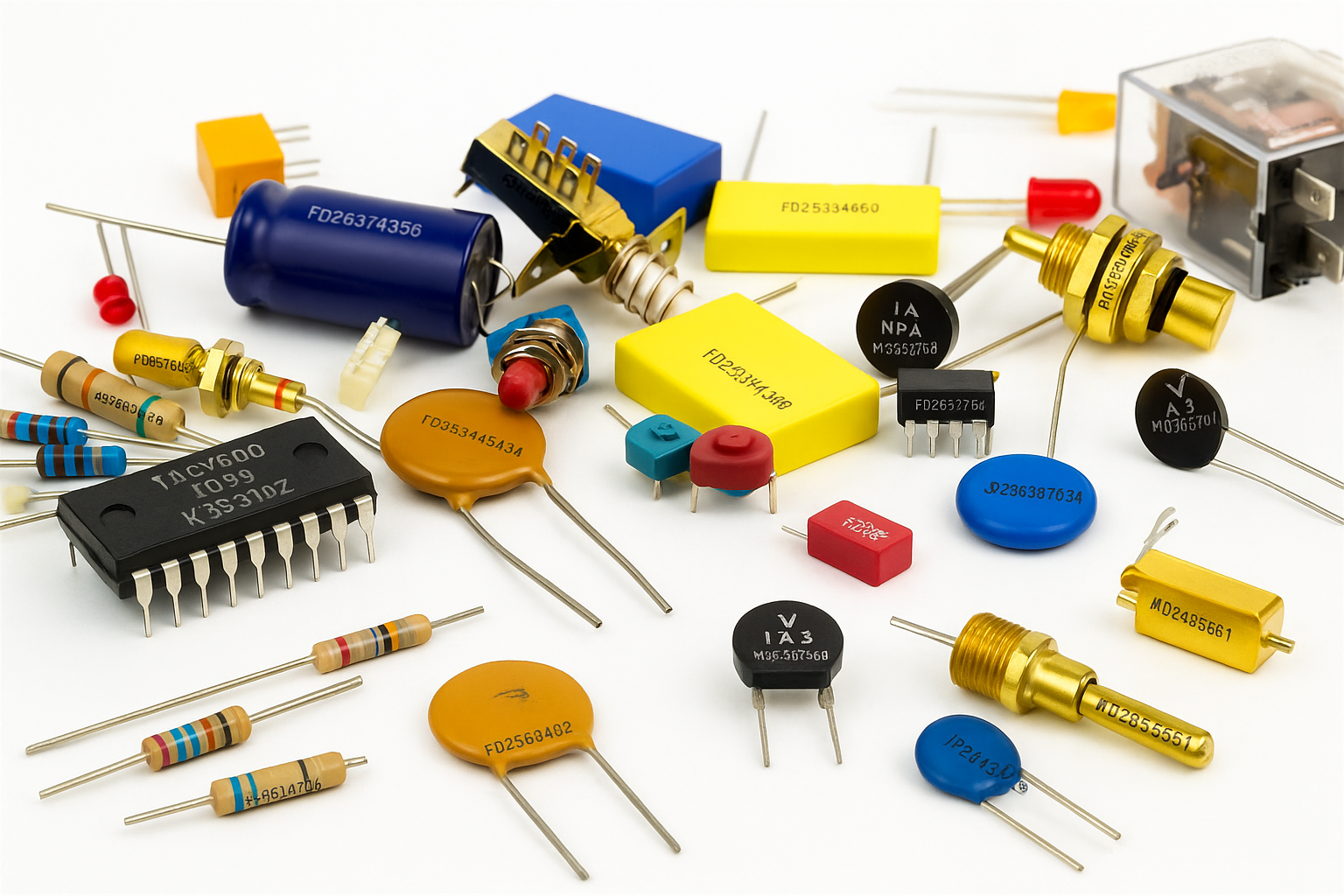

Electronics and automotive

Component identification and serial coding

Beverage and FMCG

Marking glass, PET, and metal packaging

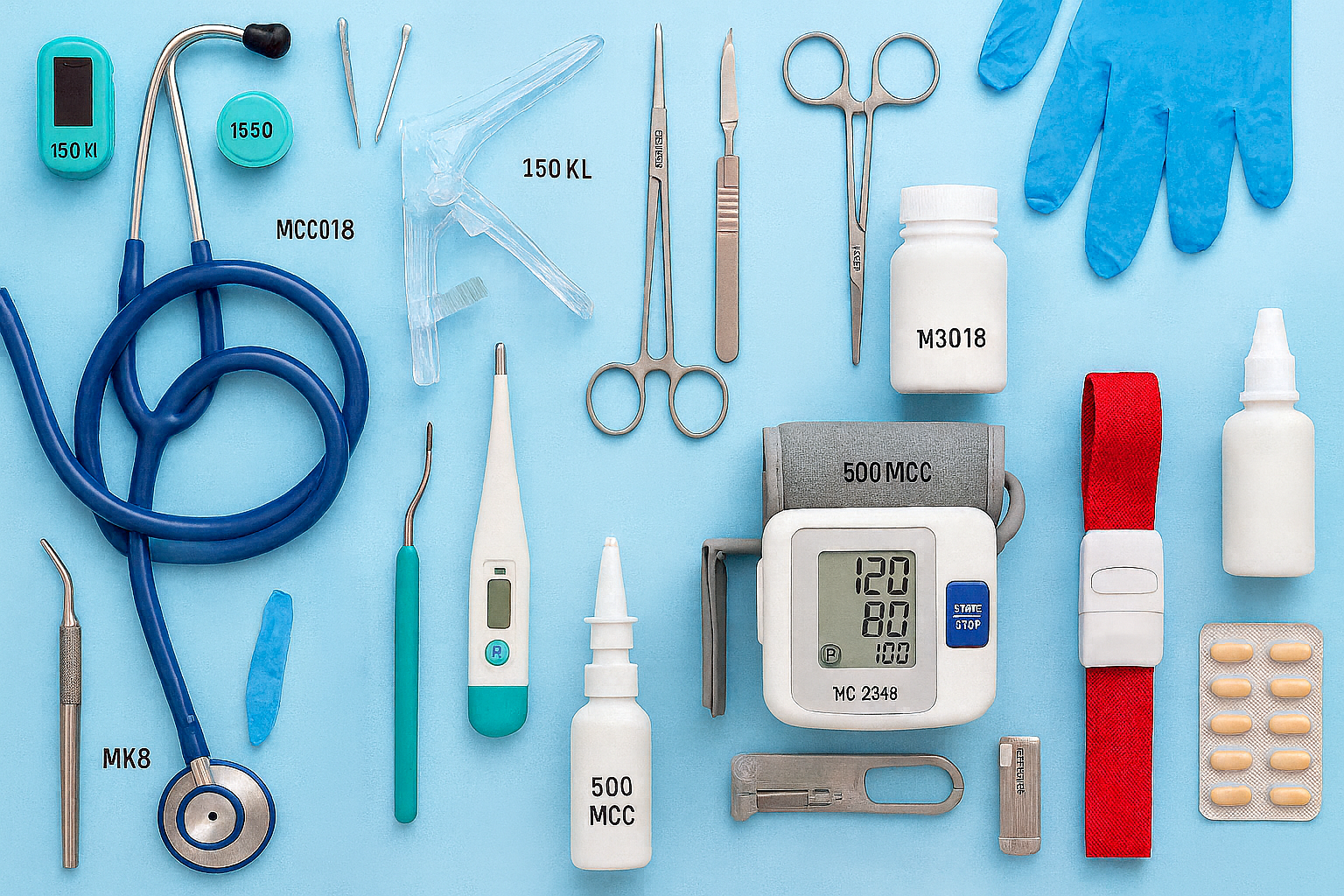

Medical devices

Permanent UDI marking and compliance labeling

No, the laser precisely alters only the top layer, ensuring the product’s structure and integrity remain intact.

High-speed, contactless printing for accurate codes on any surface.

Versatile, high-resolution coding with powerful data handling and traceability.

Precision coding for variable data on fast-moving flexible packaging lines.

Streamlined product movement for efficient, automated production lines.

High-contrast codes and text for large, porous surfaces.

Have a question or need a solution? Our team is ready to assist you.