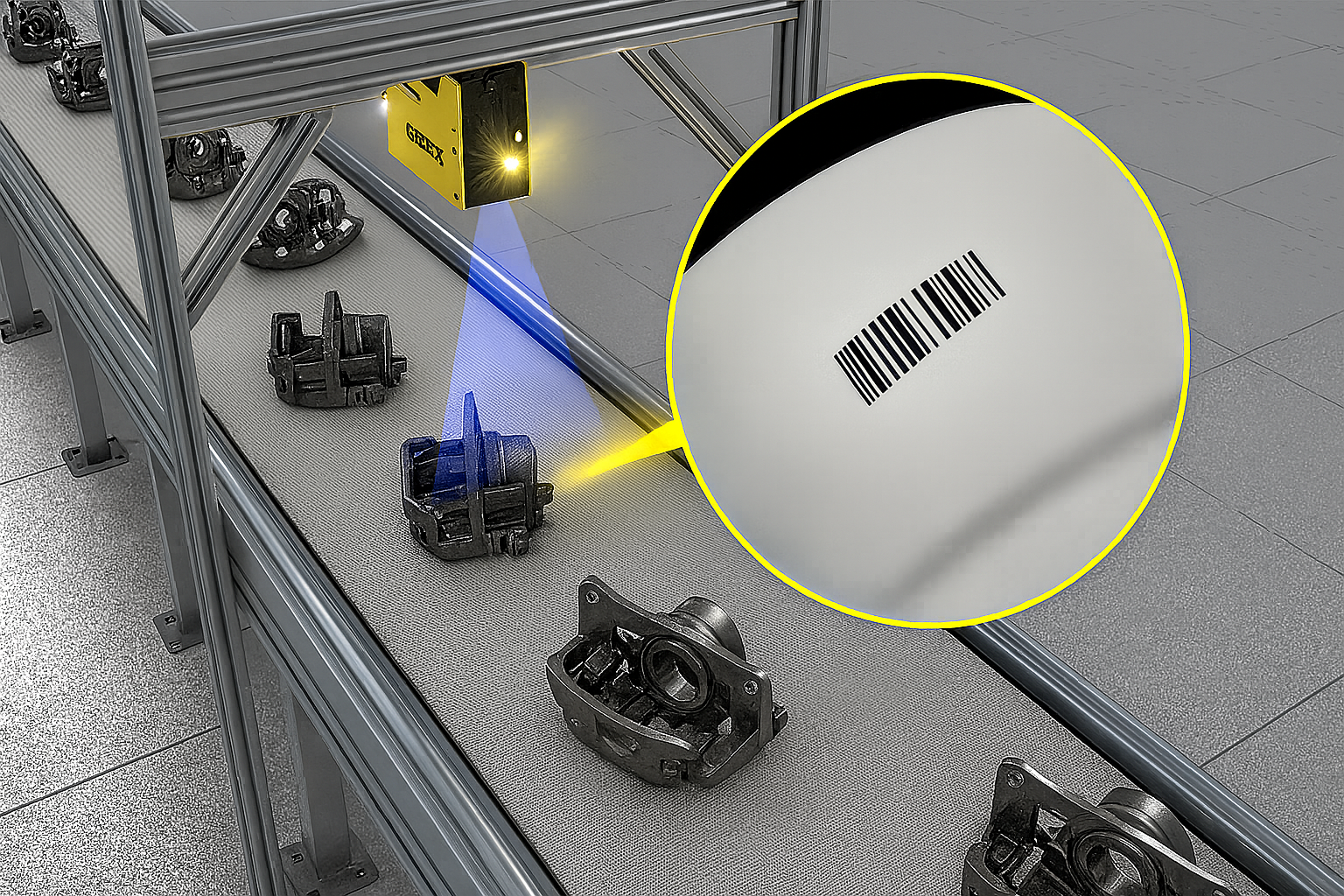

IJS’s Conveyor Systems are engineered to deliver precise, synchronized product movement across automated marking and coding operations. Designed with robust materials and modular flexibility, they ensure steady product flow, optimal print positioning, and reduced downtime. Seamlessly integrated with various printing technologies, our conveyors enhance overall production efficiency and accuracy.

These systems play a crucial role in automated packaging and inspection lines, providing consistent handling for diverse product types and sizes.

Marking and labeling lines

Smooth product transfer between printing and verification stages

Pharmaceutical and FMCG

Reliable handling for bottles, cartons, and pouches

Industrial automation setups

Synchronization with vision systems, scanners, and reject units

High-speed, contactless printing for accurate codes on any surface.

Versatile, high-resolution coding with powerful data handling and traceability.

Precision coding for variable data on fast-moving flexible packaging lines.

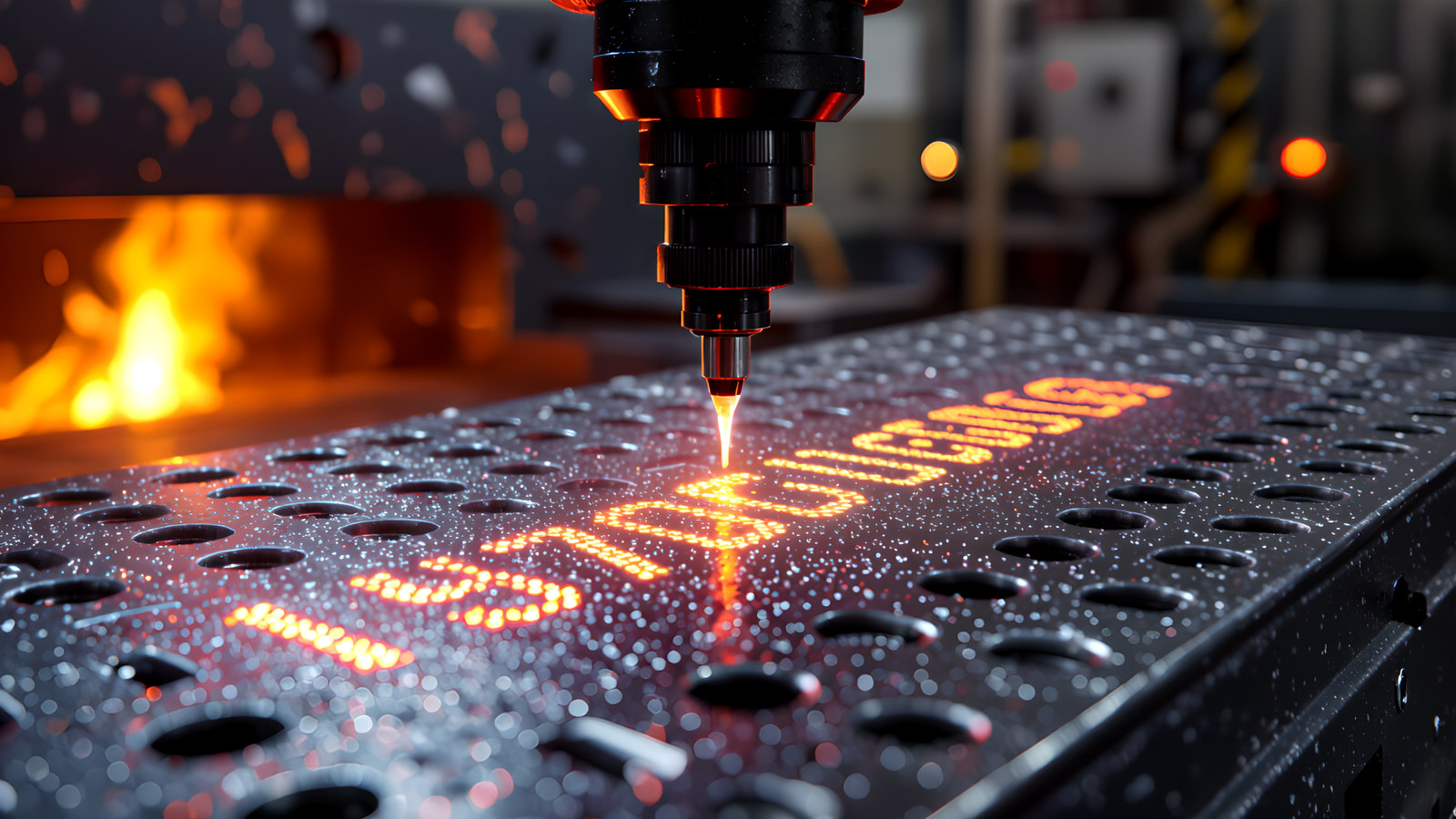

Permanent, high-precision laser marking for accurate identification and traceability.

High-contrast codes and text for large, porous surfaces.

Have a question or need a solution? Our team is ready to assist you.