IJS provides a complete range of inks, ribbons, and spare parts engineered to deliver reliable performance across diverse production needs. Our in-house R&D and testing ensure consumables are optimized for clarity, compliance, and long-term efficiency.

With consistent supply and material-specific formulations, IJS consumables keep your coding systems running seamlessly, helping you reduce downtime and maintain productivity at stable, predictable costs.

Consistent Performance

Engineered to deliver sharp, legible codes across varied materials like cartons, bottles, blisters, pouches, and more.

Reduced Downtime

High-quality formulations and durable parts minimize changeovers and maintenance, keeping production lines running.

Stable & Predictable Pricing

Local manufacturing shields you from currency fluctuations, ensuring competitive prices that remain steady over time.

Compliance Confidence

Designed to meet industry and regulatory standards across pharma, food & beverage, wire & cable, and other critical sectors.

Pigmented inks built for clear marking on complex surfaces

Fuel-resistant formulations ensuring durability under harsh exposure

Heat-curing inks for strong adhesion in high-temperature conditions

Specialized inks tested for long-term performance at extreme heat

Non-hazardous options meeting food and pharmaceutical standards

Covert security solutions including UV fluorescent inks for traceability

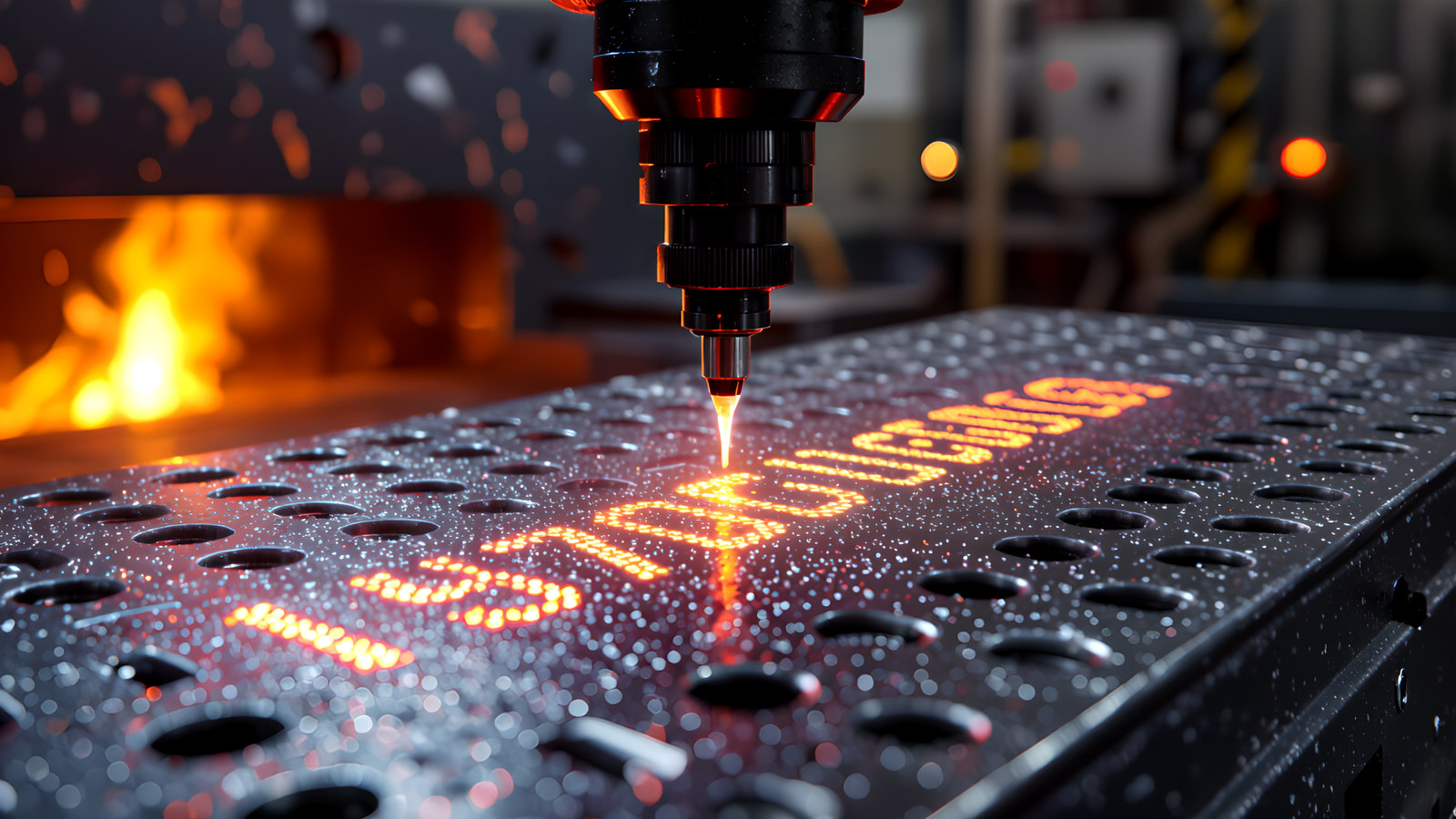

Permanent, high-precision laser marking for accurate identification and traceability.

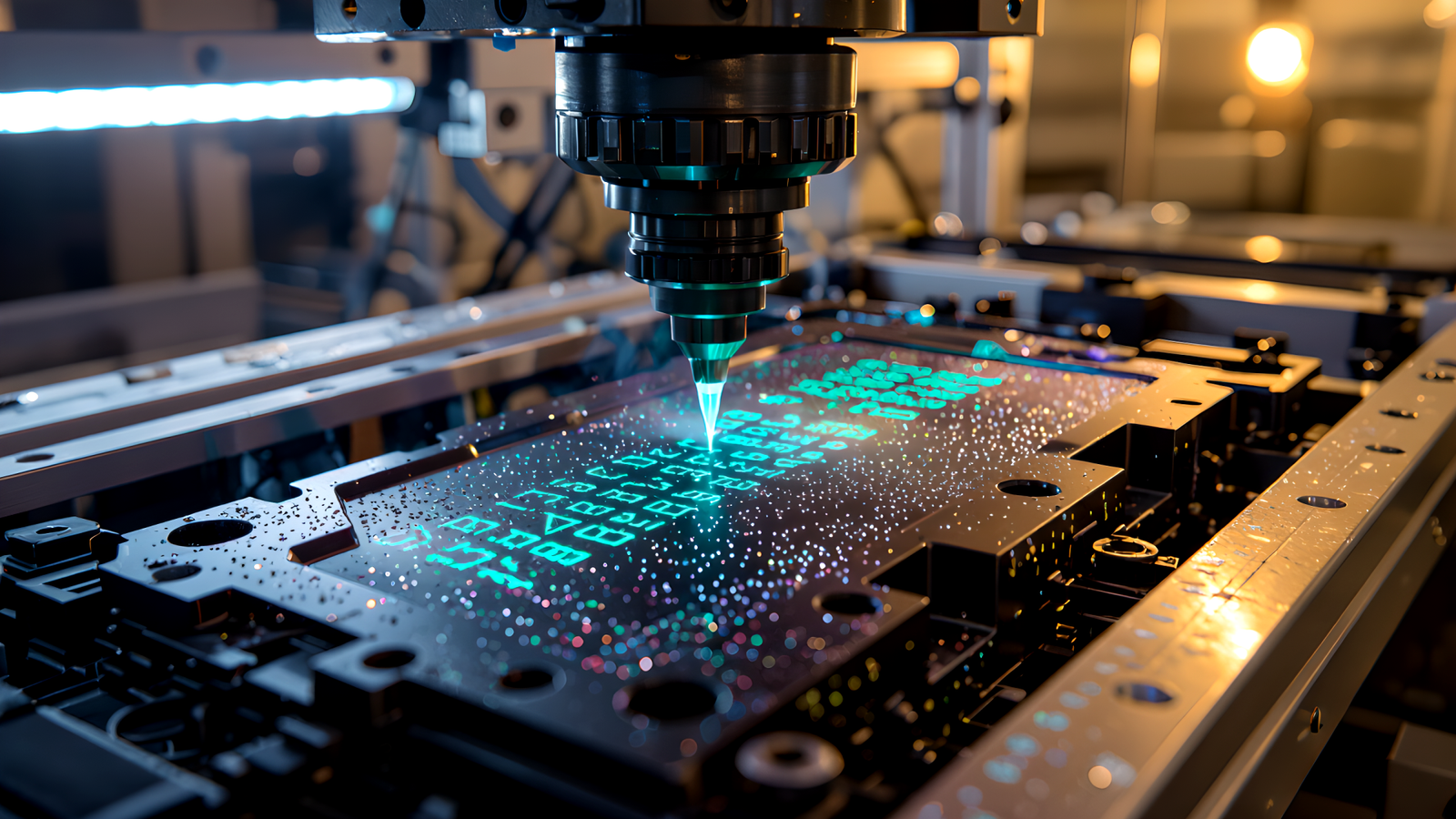

Versatile, high-resolution coding with powerful data handling and traceability.

Precision coding for variable data on fast-moving flexible packaging lines.

Streamlined product movement for efficient, automated production lines.

High-contrast codes and text for large, porous surfaces.

Have a question or need a solution? Our team is ready to assist you.